CONTACT US

Mobile Phone : 008618625531588

Fax : 0086-0371-86151367

E-mail : hlmachine001@gmail.com

E-mail : fancy001@hycfm.cn

Address : No. 285, Floor 18, Unit 1, Timing Senlin International Building, Cross Of Tianming Rd. And Dongfeng Rd., Jinshui Dist., Zhengzhou, Henan, China (Mainland)

Other machine

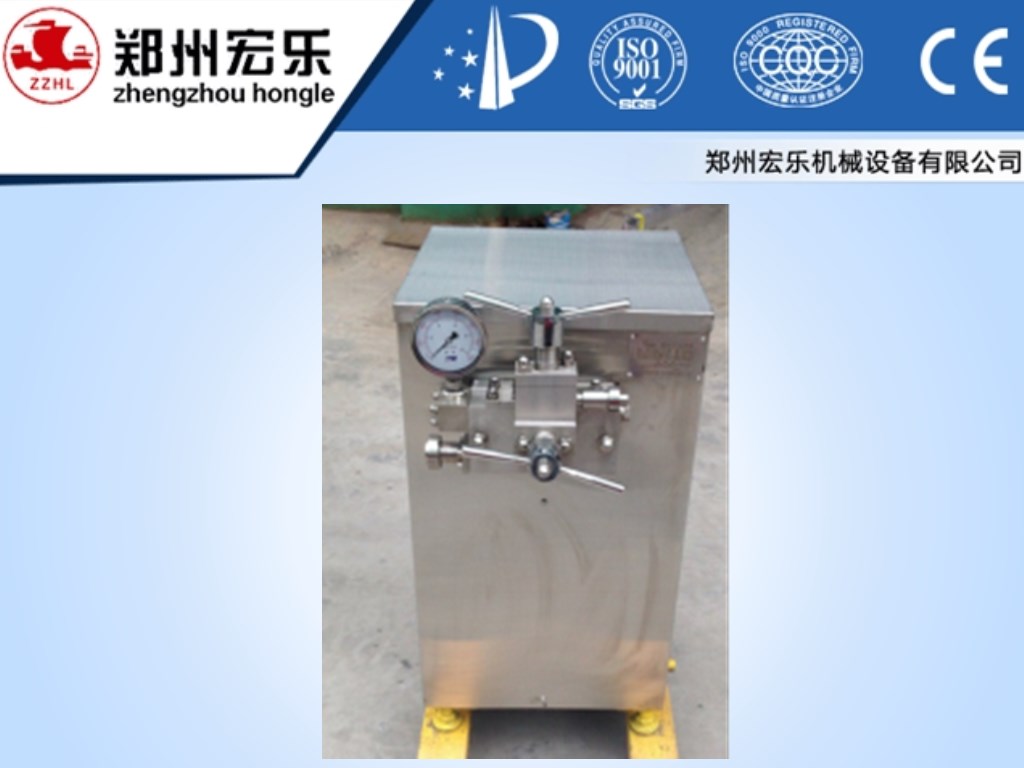

Stainless steel Milk Homogenizer

- Capcity: 500-6000 L/h

- Power: 2.2kw

- Voltage: 380v

- Ports: Qing Dao,Ning Bo

- Size: 710 *420*680mm

- Payment: T/T,Western Union L/C

(※ Click this button to inquiry)

Introduction and Features of Stainless steel Milk Homogenizer

The stainless steel milk homogenizer is the special equipment for the homogeneous refinement and high pressure transportation of liquid materials. The high pressure homogenizer is widely used in the fields of food, dairy, beverage, pharmaceutical, fine chemical and biological technology, scientific research and technology development. Homogeneous machine is mainly used for decentralized organization in the field of biotechnology and medical field sample preparation, food industry of enzyme treatment as well as in the pharmaceutical industry, cosmetics industry, paint industry, petrochemical industry, etc.. The device adopts stainless steel system, effective separation barrier on the surface of the sample and is contained, microbe homogeneous samples, samples were packed in disposable sterile homogeneous bag, and instrument contact with soft homogenization, samples, no pollution, no damage, not warming up, no sterilizing treatment, no need to wash the utensils, to meet the requirements of fast, accurate and reproducible.

Working principle of Stainless steel Milk Homogenizer

The homogenizer consist of rack, transmission case, pump body, pressure gage, homogenizer etc parts. The stainless steel milk homogenizer is vertical positioned, electromotor installed inside the rack, transmission case mounted on the rack, pump body connect with the transmission case. Electromotor drive the transmission case gear shaft bent axle through the belt, linkage slider drive the plunger make reciprocating motion. The plunger inside the pump body make the pumping and compressing movement, the pressure formed through combination valve control feed liquid. When the machine used as homogenate, it should assemble the homogenizer, the feed liquid press in the homogenizer, after homogenizing valve’s effect, the feed liquid get fully homogeneous refinement. When the machine used as high pressure pump, it should assemble the high pressure over flow device, the feed liquid press in the outlet through pump body, when the pressure exceed the setting range, the overflow valve will open automatically, form the inside discharge, when the pressure under the setting value, the overflow valve will close automatically, so the feed liquid could convey safely in the setting pressure range.

Technical parameters of Stainless steel Milk Homogenizer

| Technical parameters | Technical parameters | Technical parameters | |||

|

Processing: |

Homogenizer |

Condition: |

New |

Place of Origin: |

Henan, China (Mainland) |

|

Brand Name: |

HL |

Model Number: |

HL-0.2/25 |

Processing Types: |

Milk |

|

Voltage: |

380v |

Power(W): |

2.2-90kw |

Weight: |

depend on the size |

|

Dimension(L*W*H): |

710 *420*680mm |

Certification: |

ISO |

Warranty: |

1 year warranty for milk homogenizer price |

|

After-sales Service Provided: |

Engineers available to service machinery overseas |

Maximum pressure: |

25Mpa |

Rating pressure: |

20mpa |

|

homogenizer: |

milk homogenizer |

|

|

|

|

Please enter your demand such as Raw material type,Capacity, Feeding material size, Final product size. We will reply you as soon as possible.

- Drum Mixer Horizontal Stainless Steel Drum Mixer Flour Additive Powder Mixing machine

- Stainless Steel Multi functional Drum Type Commercial Octagonal Mixer Fully Automatic Food Seasoning Machine nut flavor mixing machine

- Continuous Drum Rotary Tumbler Mix Food Cashew Seasoning Mixer Snack Seasoning Machine