CONTACT US

Mobile Phone : 008618625531588

Fax : 0086-0371-86151367

E-mail : hlmachine001@gmail.com

E-mail : fancy001@hycfm.cn

Address : No. 285, Floor 18, Unit 1, Timing Senlin International Building, Cross Of Tianming Rd. And Dongfeng Rd., Jinshui Dist., Zhengzhou, Henan, China (Mainland)

Snack Processing Machine

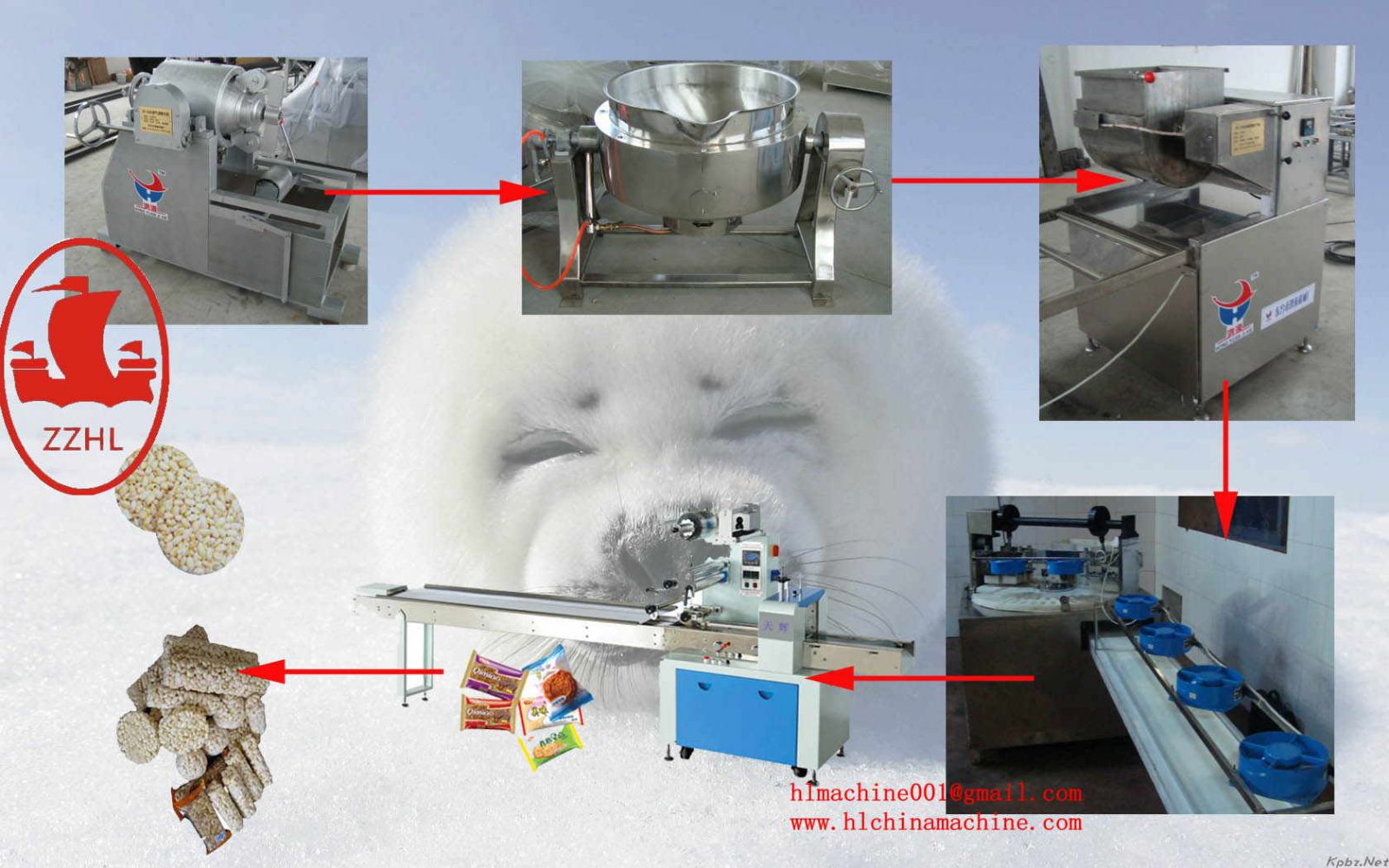

Automatic cereal cake processing line

- Capcity: 60kg/h

- Power: 0.75kw

- Voltage: 380V

- Ports: Qing Dao

- Size: 1650x800x1350mm

- Payment: T/T Western Union L/C

(※ Click this button to inquiry)

Automatic cereal cake processing line is made of stainless steel, and uses electricity, gas, steam, heat transfer oils as heating energy.

Brief produce of the rice cake processing line:

The cereal bar making processing line need four machines: air puffing machine----candy cooking machine-----mixing machine----cereal bar forming machine.

1.Large-scale Air Flow Puffing Machine(HYHT-10)

Candy cooking pot

This machine is made of stainless steel, and uses electricity, gas, steam, heat transfer oils as heating energy. it has tiltable discharging mechanism. it is widely used in food cooking and boiling .The volume can be between 50-300L。

Automatic cereal bar/puff rice forming machine (columnar or ball)

All the exterior of the machine is made with type 304# stainless steel,according with the requirement of QS standeard for food machine.the machine made up with stir mixing part,once press forming part,twice stir mixing part ,demolding part,cooling and delivering part,it is suitable for press forming for food such as rice ball ,wheat ball,popcorn ball ,rice bar,rice cake and so on.

Equipment properties and characteristics:

1,Adopting import servo electromagnetic system,which has the characteristics of advanced design,automatic control,stable operation,no impact and quiver.

2,Adopting food-level materials to design and fabricate mould and hopper,which is safe and healthy.

3,Automatic decimal aligment,automatic error correction and automatic demould of the moulding system,which has a high effeciency on the finished product.

4,Automatic material distributing,automatic baiting and automatic demould of the material enables low defective products rate

6,The diameter and thickness of the cereal can be designed and manufactured according to the customers’ demand.

Please enter your demand such as Raw material type,Capacity, Feeding material size, Final product size. We will reply you as soon as possible.

- Drum Mixer Horizontal Stainless Steel Drum Mixer Flour Additive Powder Mixing machine

- Stainless Steel Multi functional Drum Type Commercial Octagonal Mixer Fully Automatic Food Seasoning Machine nut flavor mixing machine

- Continuous Drum Rotary Tumbler Mix Food Cashew Seasoning Mixer Snack Seasoning Machine