CONTACT US

Mobile Phone : 008618625531588

Fax : 0086-0371-86151367

E-mail : hlmachine001@gmail.com

E-mail : fancy001@hycfm.cn

Address : No. 285, Floor 18, Unit 1, Timing Senlin International Building, Cross Of Tianming Rd. And Dongfeng Rd., Jinshui Dist., Zhengzhou, Henan, China (Mainland)

Snack Processing Machine

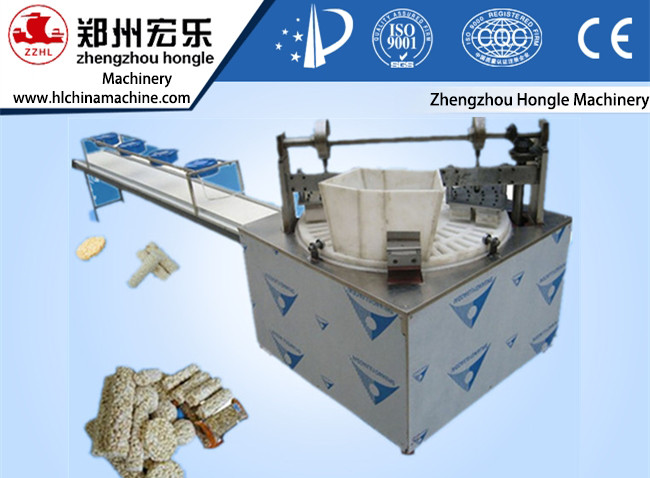

Good price of New type breakfast cereal bar forming machine with competitive price

- Capcity: 150-180kg/h

- Power: 2kw

- Voltage: 380v

- Ports: Ningbo / Qingdao

- Size: 3500*1200*800mm

- Payment: T/T,L/C,Western Union,MoneyGram, other

(※ Click this button to inquiry)

The rice cake making processing line need five machines : air puffing machine----candy cooking machine-----mixing machine----rice cake forming machine---packing machine.And then ,you can product the delicious rice cake .

Large-scale Air Flow Puffing Machine

This machine has largest capacity in air flow puffing machine. This is suitable for the puffing process for soybean , rice, corn, millet, wheat and etc.

This machine has the characteristic of big output low energy consumption, high safety factor.

Main technical parameters:

Voltage: 380V

Power: 0.75kw

Capability: 8—10kg

Volume: 60kg/h

Weight: 380kg

Dimension: 1650x800x1350

Candy cooking pot

This machine is made of stainless steel, and uses electricity ,gas, steam, heat transfer oils as heating energy. it has tiltable discharging mechanism. it is widely used in food cooking and boiling .The volume can be between 50-300L.And i recommend you use the machine with the volume of 200L.

Mixing machine

Model: hlrm-200

The mixer can mix the candy food and so on

Voltage: 380v

power 1.1kw

Capacity: 200kg/h

Inner size: 680mm*600mm

Size: 800*900*1400

Weight:120kg

Cereal bar forming machine

All the exterior of the machine is made with type 304# stainless steel,according with the requirement of QS standeard for food machine.the machine made up with stir mixing part,once press forming part,twice stir mixing part ,demolding part,cooling and delivering part,it is suitable for press forming for food such as rice ball ,wheat ball,popcorn ball ,rice bar,rice cake and so on.

Automatic High Speed Multi-Function Pillow Type Packaging Machine

Features and advantages:

1, Full macaronis computer controlling system, bearing plate conveying structure for the material. Safe and reliable.

2, There is no secondary pollution, healthy and safe, saving labor and resources.

3, Package length of photoelectric tracking automatic marking, design accurately and conveniently.

4, automatic replace of the products, there is no need to replace the former or shaper.

5, Roller type air emissions, full compliance with standards for packing.

6, widely applicable scope: Packaging substrate: high density polyethylene, hot sealing packaging film etc.

Usage of Cereal Bar making machine for sale:

This Multi function forming machine is mainly used for round ball, cylinder type by grains such as rice and wheat, corn, black rice, rice crisp, melon seeds crisp type products.

Features of Cereal Bar making machine for sale:

1. Turn disc type covers an small area, refrigeration function.

2. No need gas source, direct production does not destroy products organization

3. A rotating hopper, automatic baiting and automatic filling material

4. good Molding degree, don't stick mould.

5. Rotation system is concise, clear.

| Voltage | Power | Capacity | Volume | Weight | Dimension |

| 380V | 0.75kw | 60kg/h | 8-10kg | 380kg | 1650*800*1350m |

Please enter your demand such as Raw material type,Capacity, Feeding material size, Final product size. We will reply you as soon as possible.

- Drum Mixer Horizontal Stainless Steel Drum Mixer Flour Additive Powder Mixing machine

- Stainless Steel Multi functional Drum Type Commercial Octagonal Mixer Fully Automatic Food Seasoning Machine nut flavor mixing machine

- Continuous Drum Rotary Tumbler Mix Food Cashew Seasoning Mixer Snack Seasoning Machine